When talking about infrared thermal imagers, many people may feel unfamiliar. But many of us have seen the similar infrared thermal imaging pictures on TV.

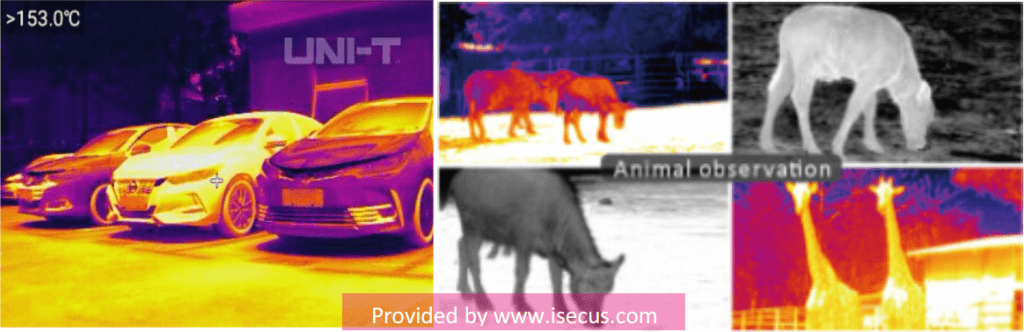

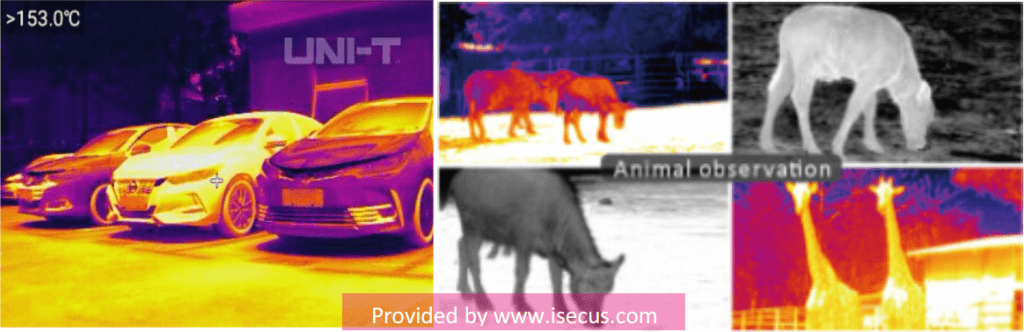

Generally, thermal imagers can be used in both military and civilian applications. For civilian use, it can be used for research and development, industrial testing, equipmentmaintenance, fire prevention, night vision, and security. It can be widely used in various application.

In nature, all objects with a temperature above absolute zero will emit infrared rays, or it can be called infrared radiation or thermal radiation. Thermal imager’s working principle is to use the infrared thermal imaging technology. By measuring the infrared radiation of the target object, it would process the signal first. By means of photoelectric conversion, the temperature distribution of the object is converted into a visual image.

Today we will analyze the latest UTi384G Thermal Imager from UNI-T. Let’s find out why a small thermal imager can achieve so many powerful functions.

Main Features:

3.5 inch touch screen

Video Recording Function

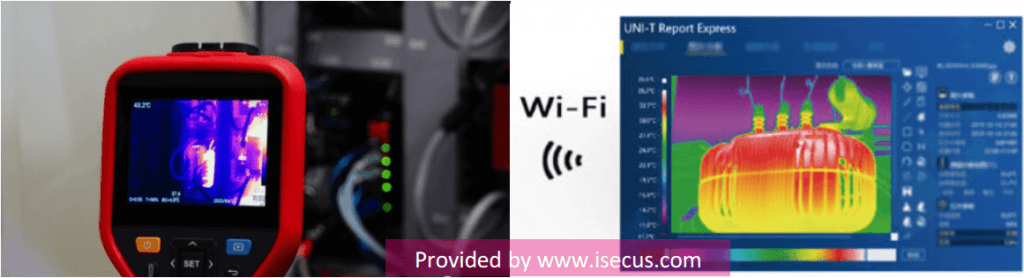

UTi384G has video recording function, which supports IR and MP4 formats. This function is very practical when facing some objects that need to be detected for a long time. The video can be transmitted through Bluetooth or WIFI, and browsed and analyzed on mobilephone or computer. You can output of the report by one-click from PC, which saves time, energy, and manpower.

7 palettes plus 4 image modes

Color palettes: 7(White hot, Black hot, Red hot, Ironbow, HC Rainbow, Rainbow, Lava)

Image modes: Thermal, Visual image, Fusion, PIP (Picture in Picture)

The camera has its own analysis function. It can realize point, circle and rectangle analysis.

Self-developed fusion image algorithm

UTi384G thermal imager adopts both visible light and infrared camera. It can capture two kinds of images and superimpose the images to make the key details clearer and more specific.

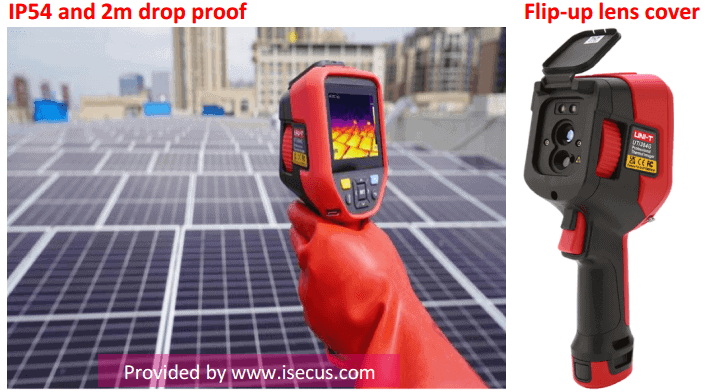

Designed for Outdoor Environment

Typical Application Sceneries

1. Motor Inspection

When there are problems such as unbalanced load, overload or wrong wiring of the motor equipment, it can be detected easily by the thermal imager. Therefore the hidden dangers can be eliminated early to avoid greater losses.

2. Power Distribution Inspection

Small problems like loose contacts and corrosion are difficult to observe with the naked eye, but can be easily found with a thermal imager. UTi384G thermal imager can be used to detect the equipment in advance to avoid fault point and reduce maintenance cost

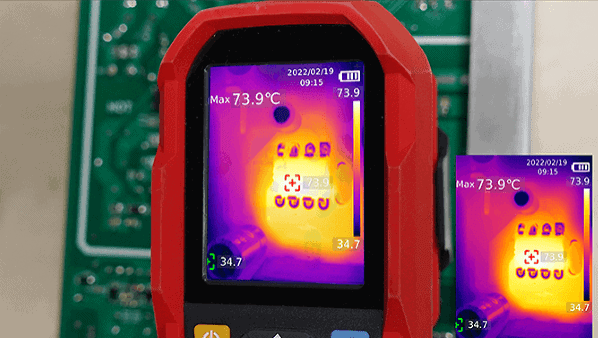

3.PCB Board Inspection

The circuit board is relatively small and ordinary detection is more laborious. However, with the help of thermal imager, we can inspect the heat generated by circuit components to measure and analyze whether the components are working normally, and locate the fault points quickly.