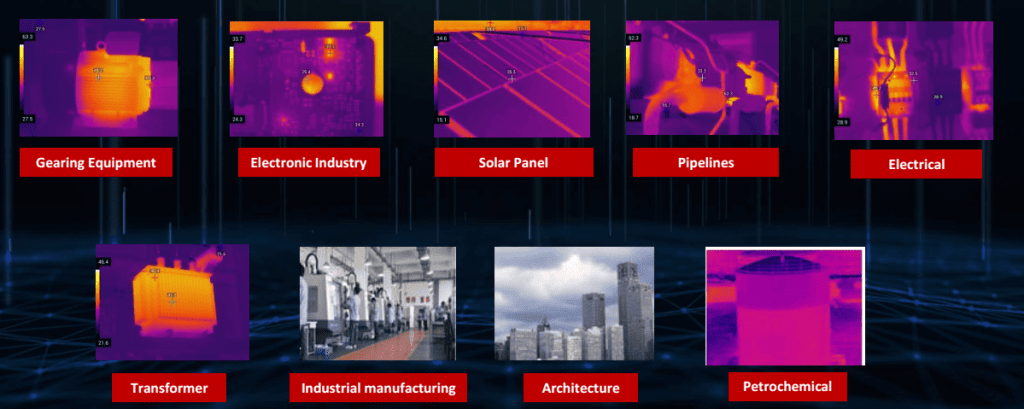

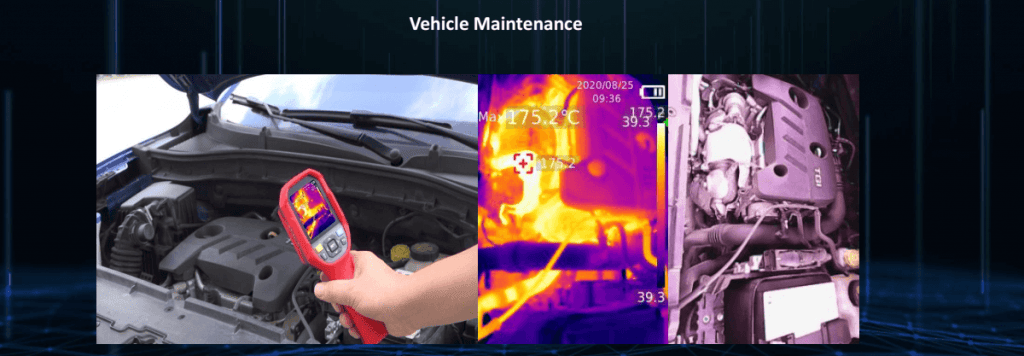

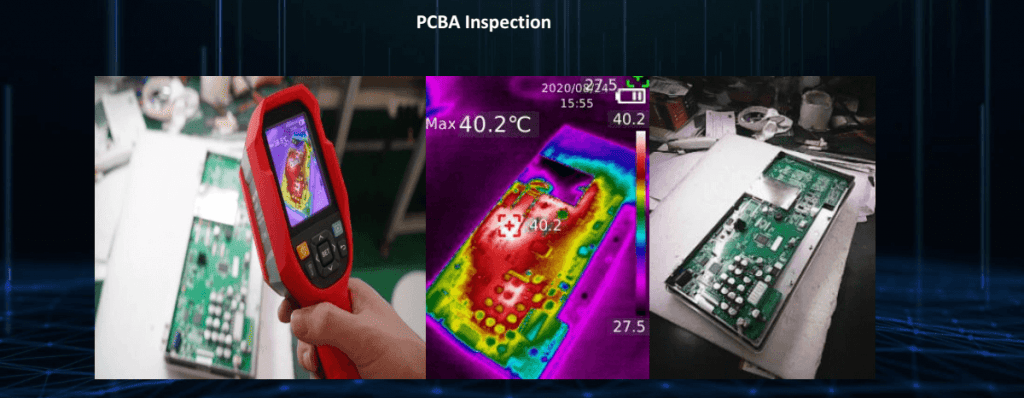

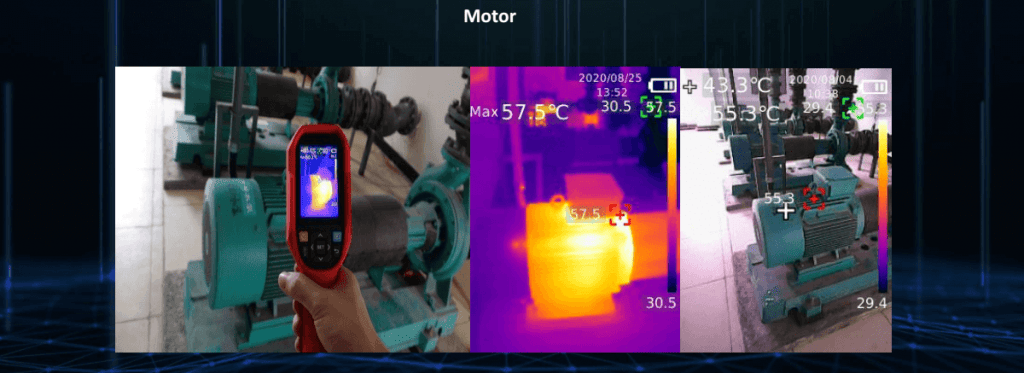

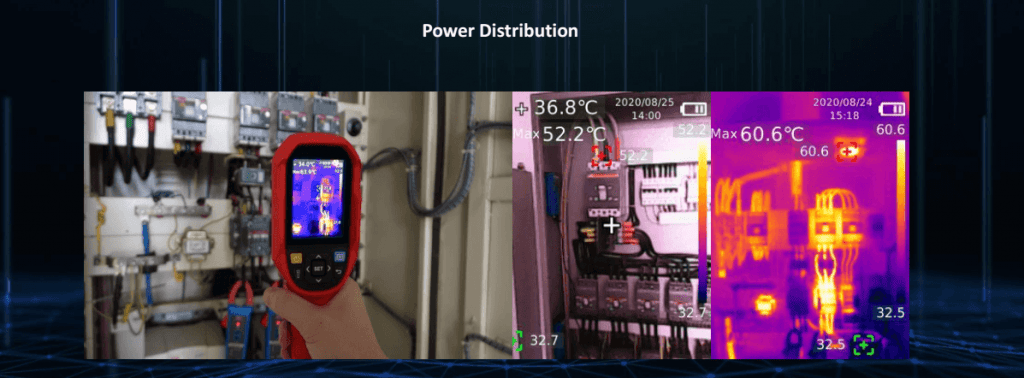

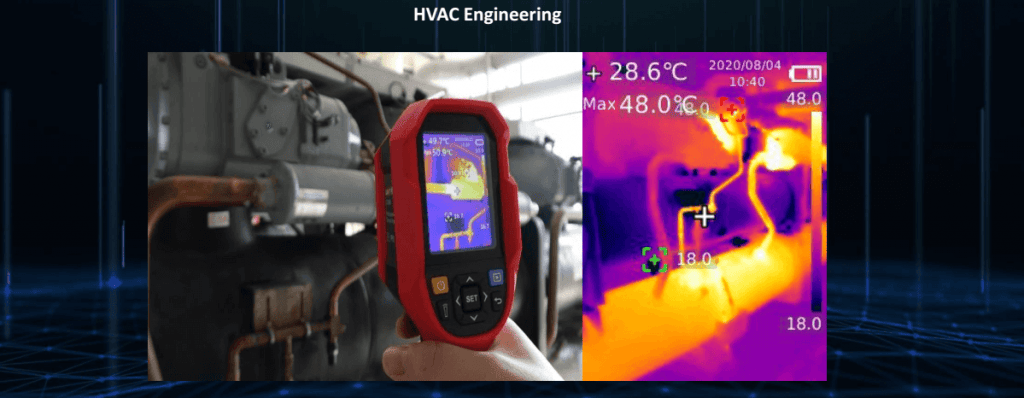

With the development of thermal imaging technology and reducing cost, more affordable, pocket-sized & handheld, and easy-to-use have been used in the industrial areas. Therough this post, you will see how iSecus Thermal Imaging cameras help you to see invisible problems instantly and efficiently. Whether it’s an electrical short, energy loss, or failing motor, our Thermal camera will help you find the problem quickly.

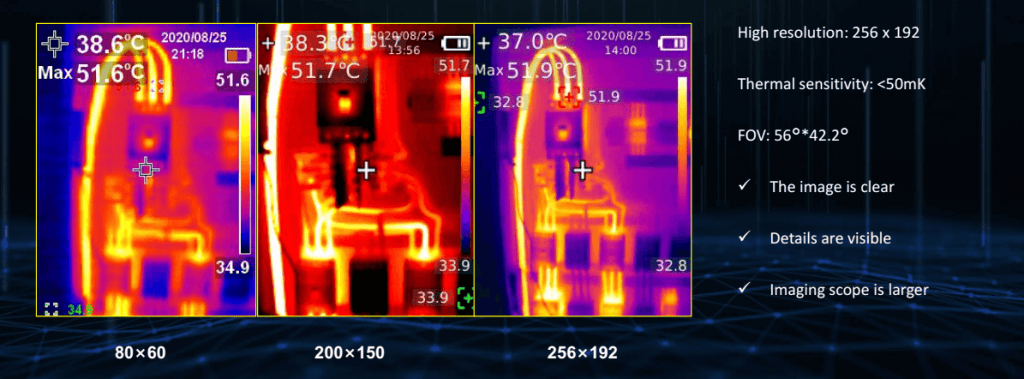

The pixels of Infrared Sensor can detect the infrared thermal radiation. High-resolution sensor has more pixels and related cost is also higher. Below pictures show the pictures differences from varied cameras.

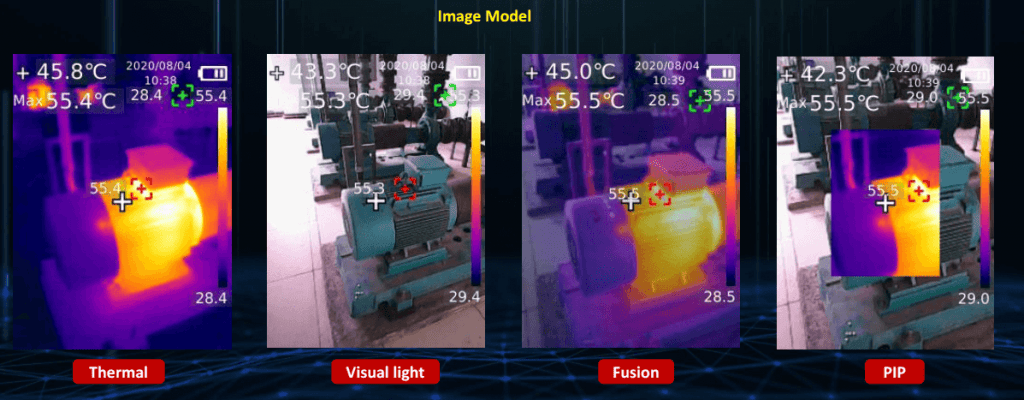

All our thermal imagers support both thermal image and visible light imager. Some models support fusion and PIP (Picture in Picture) imagers. You can easily switch the image models in camera menu.

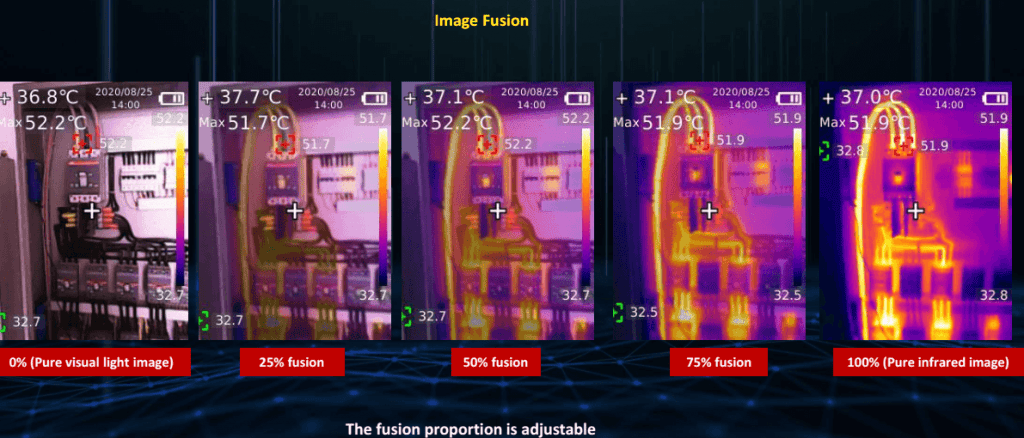

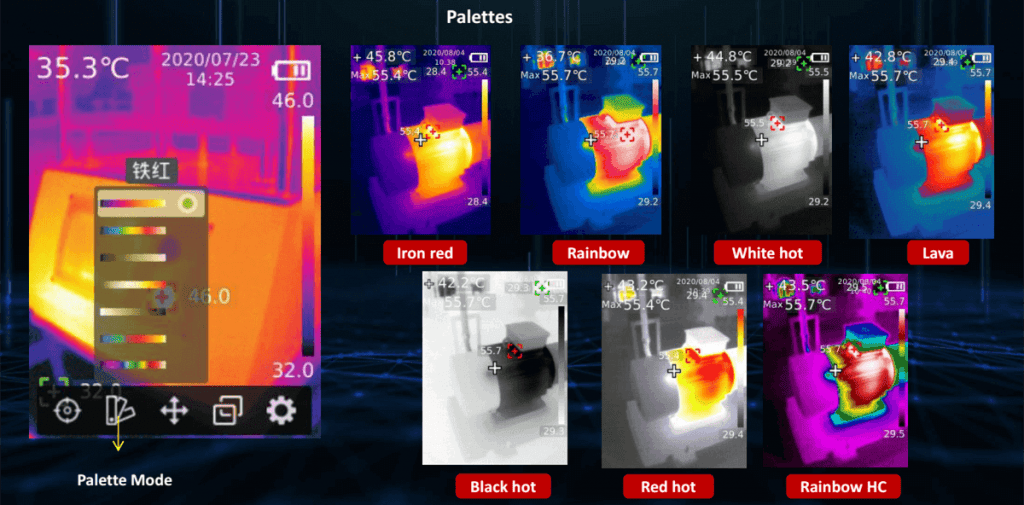

Concerning fusion proportion, it is adjustable. Besides, there are different Palettes for selection.